Weld pad level gauge transparent type

PRODUCTS

Weld pad level gauge, also known as weld pad liquid level gauge or weld pad level indicator, is a kind of liquid level gauge that is directly welded in a way of tack welding or full welding to the container walls or in the tanks.

Weld pad level gauges are available in both reflex and transparent gauge glass configurations. It is generally used for pressure vessels, vacuum vessels, tanks, reactors, filters, boiling beds and other types of closed containers or non-critical process containers.

Tanks must be relieved of pressure and drained to install and service the gauge.

Weld pad level gauges are widely used for high vibration, highly viscous liquids, or liquids with considerable amounts of solids generated in the industrial production process of petroleum, chemical, chemical fiber, pharmaceutical, food, etc.

Weld pad level gauge

Category

Weld pad level gauge transparent type

Weld pad level gauge reflex type

Features

| Range of Measurement | 300–1500 mm |

|---|---|

| Operating Pressure | 0.2–1 MPa |

| Operating Temperature | -20 °C to +250 °C |

| Chamber Material | Carbon steel or stainless steel |

| Gauge Glass Material | Borosilicate glass, aluminosilicate glass |

| Way of Observation | Visual inspection |

| Way of Connection | Flange connection |

| Notes: Other specifications are available upon request. | |

Structure

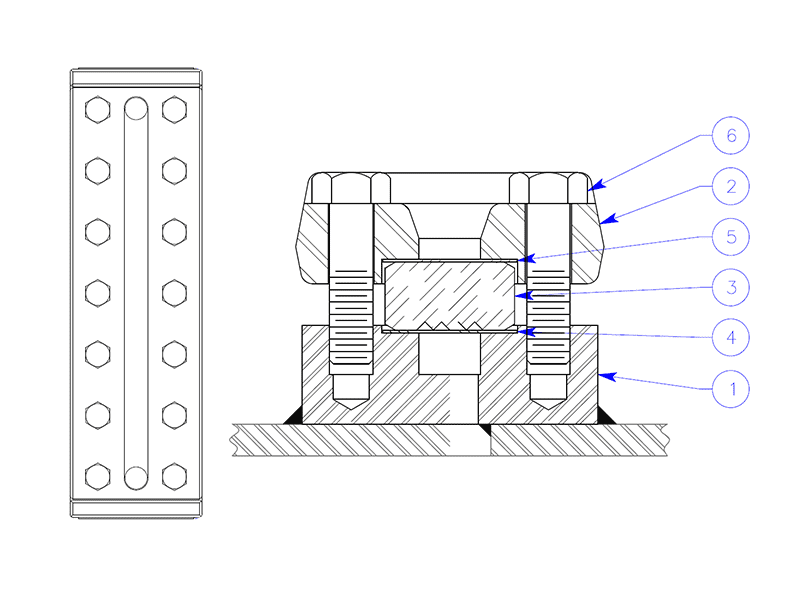

Weld pad level gauge structural diagram

Notes: Mics shields are placed between the transparent gauge glass and the medium contact surface to protect the glass from corrosion.

Working Principle

Weld pad level gauge reflex type is designed to measure the liquid level based on the laws of refraction and reflection of light. When the weld pad level gauge works, the light enters from the smooth surface of the glass vertically, and it is then refracted within the liquid. In the event of the light striking the area of the glass covered by liquid, the area appears dark due to the light refraction; in the event of the light striking the area covered by gas or air, the area appears bright due to the full reflection of the light.

As a result, the weld pad level gauge can be used to observe the liquid level changes by discriminating the bright and dark areas of the light.

Notes: The working principle of weld pad level gauge transparent type is the same as the weld pad level gauge reflex type

Weld pad level gauge reflex type working principle

Application

Weld pad level gauges are widely used in petroleum, chemical, chemical fiber, pharmaceutical, food industries, etc.

For reactors in petrochemical plants

For pressure vessels in chemical plants

Something you want to ask?