Circular aluminosilicate glass for sight glass

PRODUCTS

Aluminosilicate Glass refers to glass that has aluminum oxide in its composition. It is crystal clear and has good chemical stability, electrical insulation, mechanical strength and low thermal expansion coefficient. It is widely used for manufacturing gauge glass and sight glass. Moreover, aluminosilicate glass is also an integral part of mica-gasket-assembly. And mica gasket assembly is an accessory of liquid level gauge sight glass.

Reflex gauge glass is used to read the liquid level of the boiler or instruments and the grooves can make the liquid level clearer.

Specification

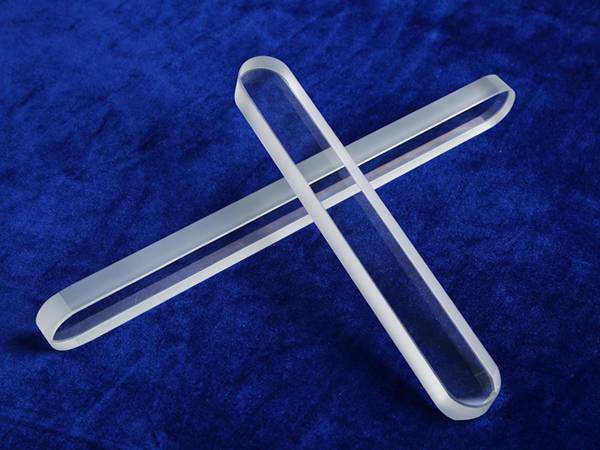

Circular aluminosilicate glass for sight glass

Rectangular aluminosilicate glass for gauge glass

Aluminosilicate glass and borosilicate glass have similar properties. However, the former has greater chemical durability and can withstand higher operating temperatures. We may see these differences from the table below.

| Material Properties | Aluminosilicate Glass | Borosilicate Glass |

|---|---|---|

| Density (@ 18 °C) | 2.630 kg/m3 | 2.230 kg/m3 |

| Modulus of elasticity (Young’s) | 81 GPa | 64 GPa |

| Coefficient of linear expansion | 4.60 × 10-6 °C | 3.25 × 10-6 °C |

| Softening point | 910 °C | 821 °C |

| Thermal shock resistance | 300 °C | 160 °C |

| Index of refraction (@ 380–780 nm) | 1.500 | 1.474 |

| Working temperature (maximum) | 660 °C | 230 °C |

Specification

Technical Notes:

Application

Rectangular aluminosilicate glass is generally processed into glass level gauge of all sizes while round aluminosilicate glass is generally processed into all types of sight glass.

Rectangular aluminosilicate glass is processed into gauge glass.

Round aluminosilicate glass is commonly used for sight glass.

Something you want to ask?