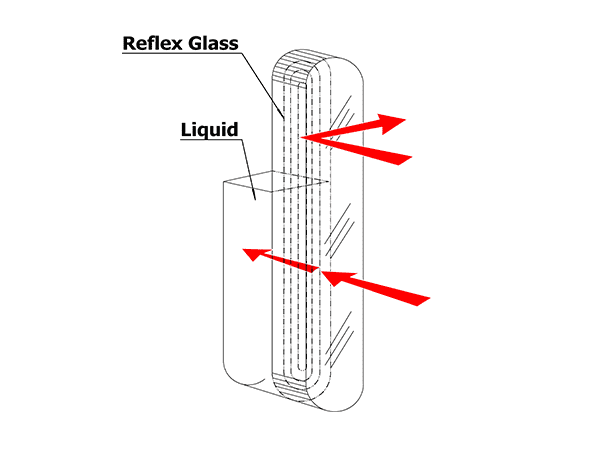

Reflex level gauge structure diagram

PRODUCTS

Reflex level gauge, also known as reflex liquid level gauge or reflex glass level gauge, is designed to indicate the liquid level based on the difference in the refractive indices of liquid and vapour. It is highly recommended for colorless liquid.

Reflex level gauge is made in hermetically sealed structure with a reflex gauge glass inside. The reflex gauge glass consists of a smooth face towards the operator and a face having prismatic grooves with section angle of 90° fitted towards the liquid chamber. It is then connected to the vessel to be observed with flanges.

It offers a clear image of the liquid level and reduces the risk of distortion or inaccurate reading, giving a clear, visualized reading. Meanwhile, it can be used in a variety of combination to expand the observation range. In addition, it also has a self-closing function to effectively avoid economic losses and casualties caused by accidents.

Reflex level gauges are widely used for the liquid level measurement of water heaters, deaerators, boiler drums and other types of containers in the fields of petroleum, chemical, power, metallurgy, pharmaceutical, etc.

Reflex level gauge

Features

| Range of Measurement | 300–2000 mm |

|---|---|

| Operating Pressure | 1.6–6.4 MPa |

| Operating Temperature | ≤ 450 °C |

| Chamber Material | Carbon steel or stainless steel |

| Gauge Glass Material | Borosilicate glass, aluminosilicate glass |

| Surface Treatment | Galvanized, power coated, etc. |

| Visible Range | 100–300 mm |

| Way of Observation | Visual inspect from the front view |

| Way of Connection | Flange connection |

| Note: Reflex level gauges can be customized to match up with the size and shape of containers. | |

Structure

Reflex level gauge structure diagram

Working Principle

The reflex level gauge is designed to measure the liquid level based on the laws of refraction and reflection of light.

The contact surface between the glass and the liquid is prism-shaped, while the surface for observation is smooth. When the light enters from the smooth surface of the glass vertically, it is then refracted within the liquid, and is not reflected by the inner wall of reflex level gauge.

In the event of the light striking the area of the glass covered by liquid, the area appears dark due to the light refraction; in the event of the light striking the area covered by gas or air, the area appears bright due to the full reflection of the light.

As a result, the reflex level gauge can be used to observe the liquid level changes by discriminating the bright and dark areas of the light.

Reflex level gauge schematic diagram

Category

1-section reflex level gauge

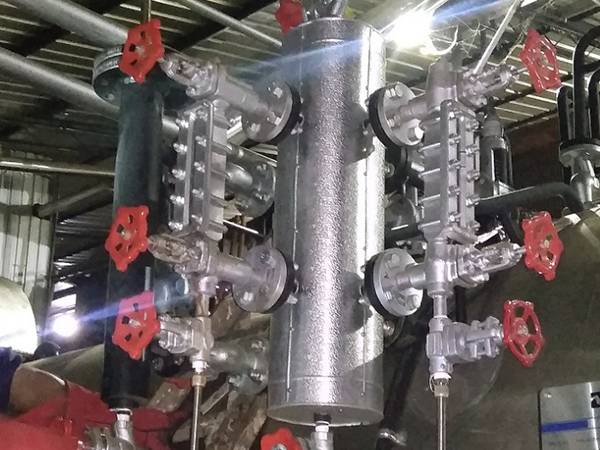

Multiple-section reflex level gauge

Notes: This multiple-section reflex level gauge contains 2 and above reflex gauge glasses and is suitable for the liquid level measurement of large containers.

Application

Reflex level gauges are widely used in the fields of petroleum, chemical, power, metallurgy and pharmaceuticals, etc.

For chemical plants

For petrochemical plants

For metallurgic plants

For thermal power plants

Something you want to ask?